In apparel manufacturing, the choice of hangers in production, quality control, storage, and transportation directly impacts efficiency, product quality, and operational costs. As a company specializing in hanger solutions, we offer a range of efficient, practical hanger options tailored to the unique needs of apparel factories, helping them manage costs and maximize productivity across each stage.

1. Hanger Requirements for Production Processes

On production lines, garments are transferred frequently between workstations, which demands high durability and ease of use from the hangers. We recommend industrial-grade plastic and lightweight metal hangers. Industrial plastic hangers are impact-resistant and affordably priced, making them ideal for bulk purchasing and high-frequency use, where cost-effectiveness is crucial. Lightweight metal hangers, though slightly more expensive, offer superior strength and durability, making them suitable for factories with greater durability needs. This balance of material and durability provides cost-effective choices without increasing budget constraints.

2. Optimal Choices for Quality Control and Display

In quality control, each finished garment is hung for close inspection of stitching, cuts, and other details, requiring hangers that support both display and garment protection.

Metal hangers with non-slip coatings and plastic hangers with foam-padded shoulders are ideal options. Metal hangers offer a sturdy structure and non-slip design that prevents garment slippage, making them suitable for displaying premium items.

Foam-padded plastic hangers, which are budget-friendly, provide both non-slip properties and garment protection, helping maintain the garment’s shape during prolonged hanging. Both options offer high cost-effectiveness for quality control and display needs.

3. Efficient Storage and Space Optimization

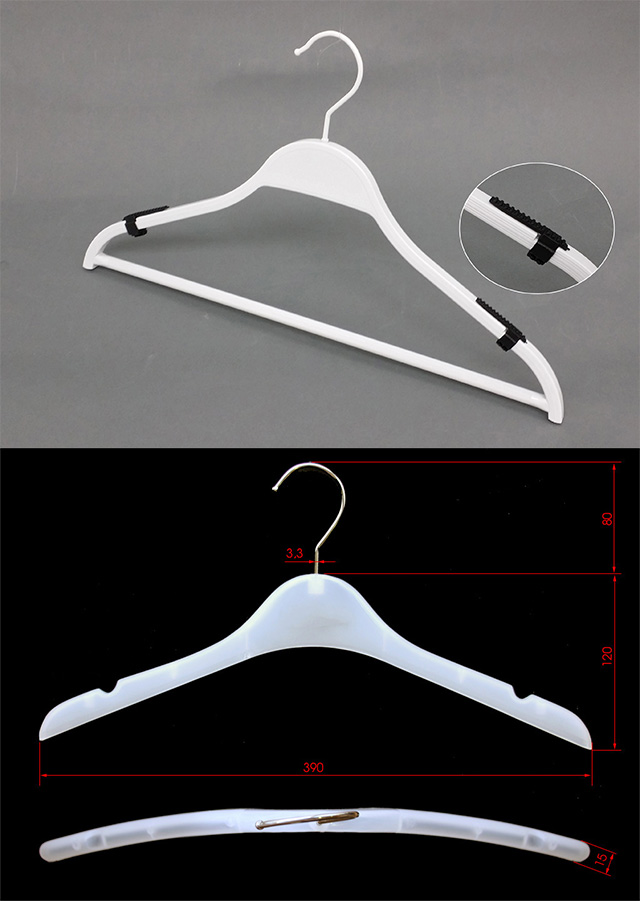

Given that factories often face limited storage space, hangers in the storage phase need to be practical and space-saving. We recommend thin plastic hangers made from high-quality engineering plastics. These hangers are lightweight yet durable, resisting deformation while allowing for efficient arrangement of more garments without compromising garment shape. Thin plastic hangers are highly economical, making them an ideal choice for bulk purchasing and maximizing storage space efficiency.

4. Hanger Selection for Safe Transportation

During transportation, protecting garments from damage and deformation is essential. We suggest metal hangers with reinforced coating or high-density non-slip plastic hangers. The reinforced coating on metal hangers increases wear resistance, making them suitable for challenging transport conditions, ensuring garment safety and reducing costs associated with rework or repairs. High-density non-slip plastic hangers, while less costly, provide solid non-slip performance, minimizing garment movement during transit and protecting garments within budget constraints.

5. Customized Comprehensive Solutions

Understanding that each factory’s production requirements, storage conditions, and transportation needs vary, we offer customizable hanger solutions tailored by material, size, and function to meet specific factory demands. Whether factories seek cost-effective bulk purchases or premium, customized options, our team will design solutions that best meet their operational needs while controlling costs.

Conclusion

Apparel factories have distinct requirements for hanger materials and functionality at each stage, with cost-effectiveness being a priority for all. Through careful selection of materials that balance durability, functionality, and affordability, we offer various high-value hanger solutions to help factories increase efficiency, optimize space usage, and ensure product quality. We are committed to providing professional, efficient, and economical hanger solutions that enhance overall operational effectiveness for apparel factories.

Please contact us by info2@headht.com

Or you can purchase directly on our website koobayhome.com